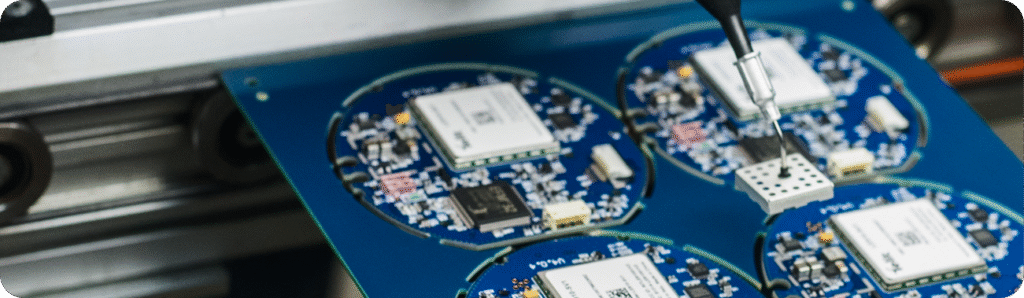

Rapid PCB Prototyping | Quote in 48 Hours

Get rapid PCB prototyping from a U.S.-based electronics manufacturer that delivers fast, precise, and production-ready assemblies. What is Rapid PCB Prototyping Rapid PCB prototyping is the process of quickly assembling and testing printed circuit boards (PCBAs) to evaluate and refine electronic designs before full-scale production. These builds are typically low-volume, fast-turn projects that allow engineers […]

Lead-Free Soldering: Why Does It Matter for PCB Assembly?

One of the most significant shifts in recent decades is the move toward lead-free soldering in printed circuit board assembly (PCBA). What began as a response to environmental and health concerns has become a new global standard, reshaping how assemblies are built and how they reach the market. The Rise of Lead-Free Soldering Solder contained […]

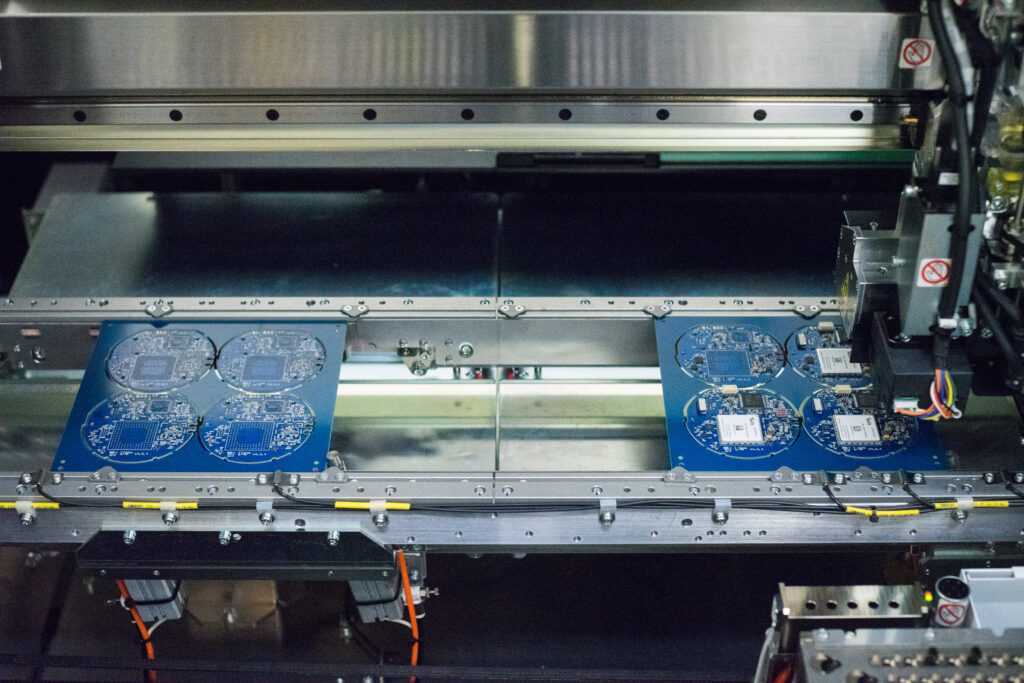

Turnkey Contract Manufacturing: Save Time & Cut Costs

Each step of making a product can cause delays, increase costs, or lead to mistakes if not appropriately managed. Supply chains can be long, and shortages of parts are common; even small mistakes can delay launch dates or increase costs. That’s why many companies rely on turnkey contract manufacturing, choosing one trusted manufacturing partner instead […]

Fast Turn Prototype PCB Board: From Idea to Design

A fast-turn prototype PCB board is designed to minimize the distance between concept and reality. Instead of waiting weeks to validate a design, engineers can quickly build, test, and adjust hardware, turning ideas into functional boards that drive faster innovation and reduce costly missteps. This process transforms uncertainty into tangible progress, giving teams the insight […]

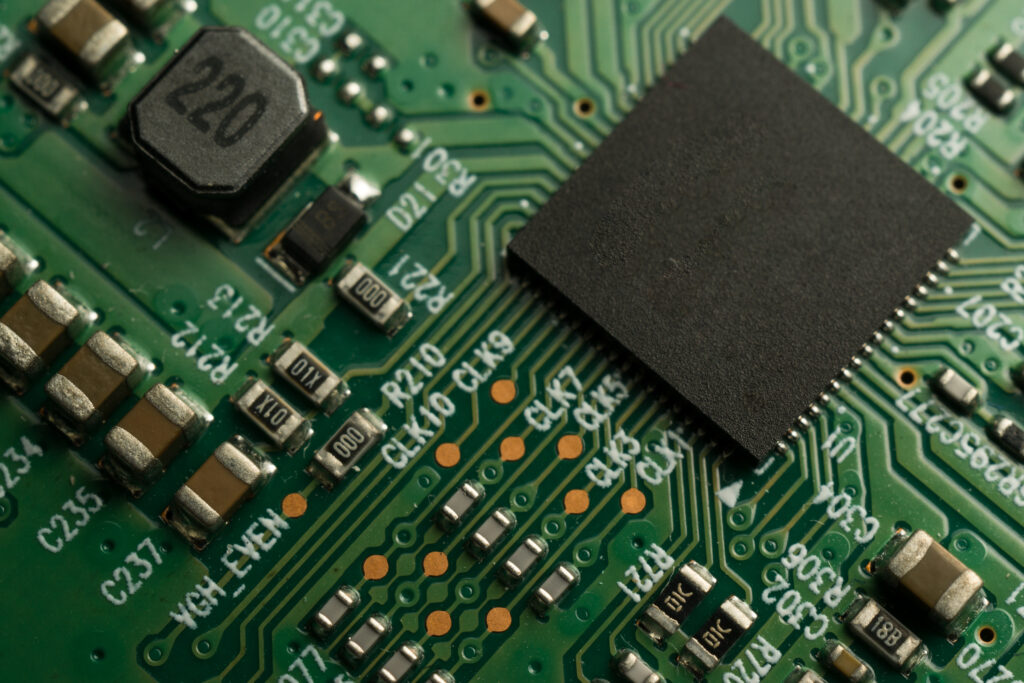

PCB Rework: Avoid Costly Redesigns

In electronics manufacturing, a misplaced component, a solder bridge, or an unexpected flaw can bring production to a stop. Every stage of building a printed circuit board carries risk—what looks perfect in design software may behave differently once real materials are involved. Even small errors, like misaligned pads or cold solder joints, can cause failures […]